Redesign of Existing Retail Product

Background

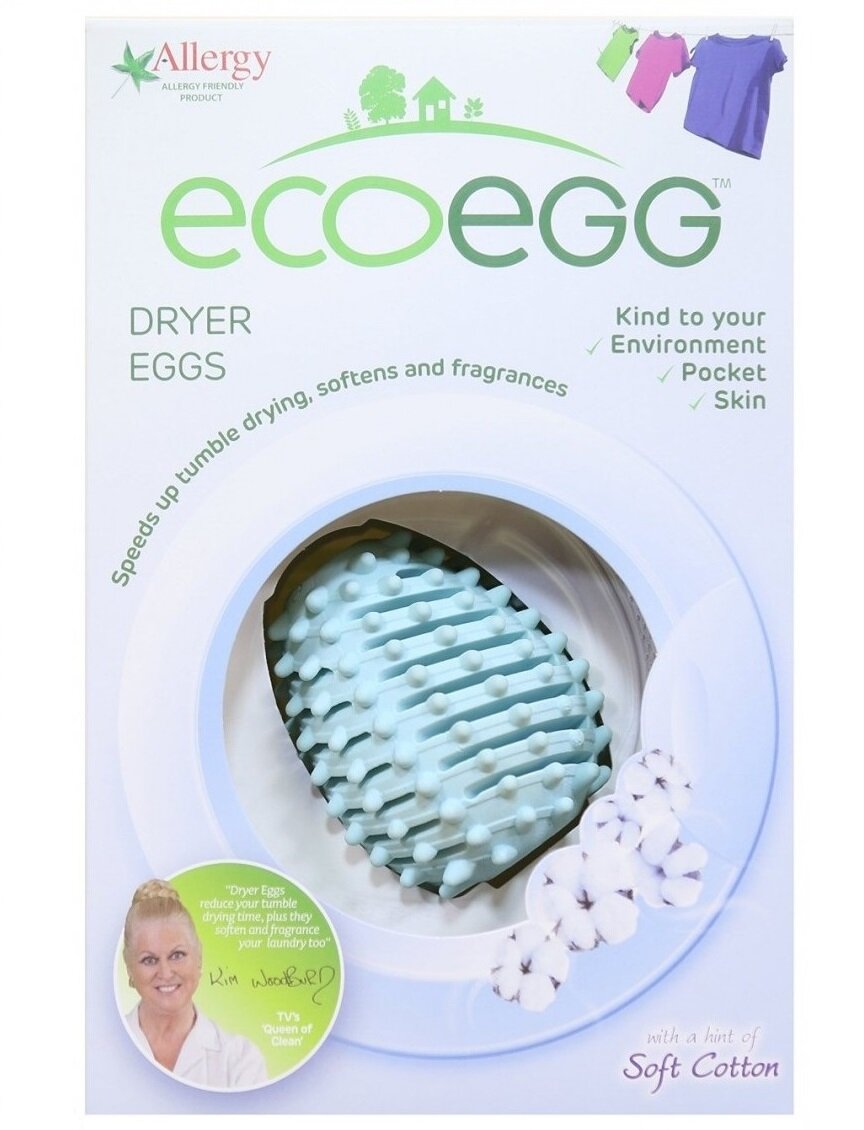

JNDC were approached by ecoegg to redesign their existing dryer egg, a product that is used inside tumble dryers to reduce drying time and soften and fragrance clothes. The initial specifications included areas such as keeping the same look as the original dryer egg and to hold the existing fragrance stick within the product.

Development

The original dryer egg was made up of 5 separate sections (shown in purple below). JNDC focused on part reduction as well as efficiency of the product resulting in a single part design. Tooling was highly complex to produce. However, the cost benefit of no assembly led to a quick return on investment for the tooling.

Solution

With the new design being manufactured as a single part, this removed all assembly costs and completely removed the risk of the product falling apart in the tumble dryer. The dryer egg has sold in significant volumes via QVC shopping channel through to being available on the high street at outlets such as Lakeland.